If you are in the UK, you’re in luck! Here at Springpack, we offer next working day delivery to mainland UK on all orders before 3:30pm.

Choosing the Best Void Fill for Your Needs

Choosing the best void fill for your needs

There is a plethora of void-fill solutions available for your packaging process. All voidfill solutions have the same purpose, and all have their own pro’s and cons.

In this guide, we will explore the most common types of void fill packaging and explore which options suit which operations.

Void fill products work to (you guessed it!) fill the void – meaning there is less room for your products to move around during transit. It also works to shock absorb, which prevents shocks that may damage your products during transit.

It creates a force within the box, making the box and therefore the products inside, less likely to be crushed in transit.

So whether you’re a manufacturer of car bumpers sending them to the other side of the country, or have sold a designer baseball cap on Vinted, void fill can be your best friend for reducing damages during shipping.

Paper and cardboard products are protection methods favoured by many companies, as they reduce the amount of plastic used in transit.

All paper products supplied by Springpack are high quality and can be reused many times. At the end of the product’s useful life, our paper products are 100% kerbside recyclable and can be disposed of in the end user’s recycling bin.

An additional benefit of paper products is that they are a visual queue to the end user on how to correctly dispose of it.

Providing they have no labels or plastic attached, paper and cardboard are biodegradable materials! Paper and cardboard products are great for adding to a home compost bin, as they are carbon-rich and are great for retaining moisture.

Void Fill Paper is sold on the roll or in the box. The box contains 100% natural recycled paper. The box is both a practical storage method for the centre feed roll and works as a practical and easy to use dispenser.

To use paper, simply remove a length and scrunch it into a ball. Tuck the scrunched paper around the edges of the product, on top and underneath.

Paper Bubble Wrap also known as Globular Embossed Paper is available on a roll, and works in place of traditional bubble wrap.

Made from 100% recycled paper, it is reusable and 100% recyclable at the end of it’s useful life.

Paper bubble wrap can be used to wrap around products to protect them, as well as offers cushioning to corners.

Ripad Paper is formed into pads using a Ri-Fill machine. It can be used for several different void fill techniques:

- Layering, which protects the vulnerable areas of the item

- Laying along the bottom of the box in the shape of an X (Known as a Maltese Cross), which offers corner-to-corner and all-round protection.

- Coiling, a coil of paper both top and bottom of a carton works to suspend the product, meaning impacts during shipping can’t damage it.

- Snake, utilising a long “Snake” of the paper around the products being shipped.

- Blocking & Bracing, tight coils of paper strategically positioned to suspend the item during transit.

Honey Comb Paper, also known as Hive Wrap is a packaging innovation that can be used in place of bubble wrap in many applications.

Made from pure kraft paper, this method of protecting your products works by being perforated during the manufacturing process to make it stretch. It is perfect for shipping delicate items, and is fully recyclable

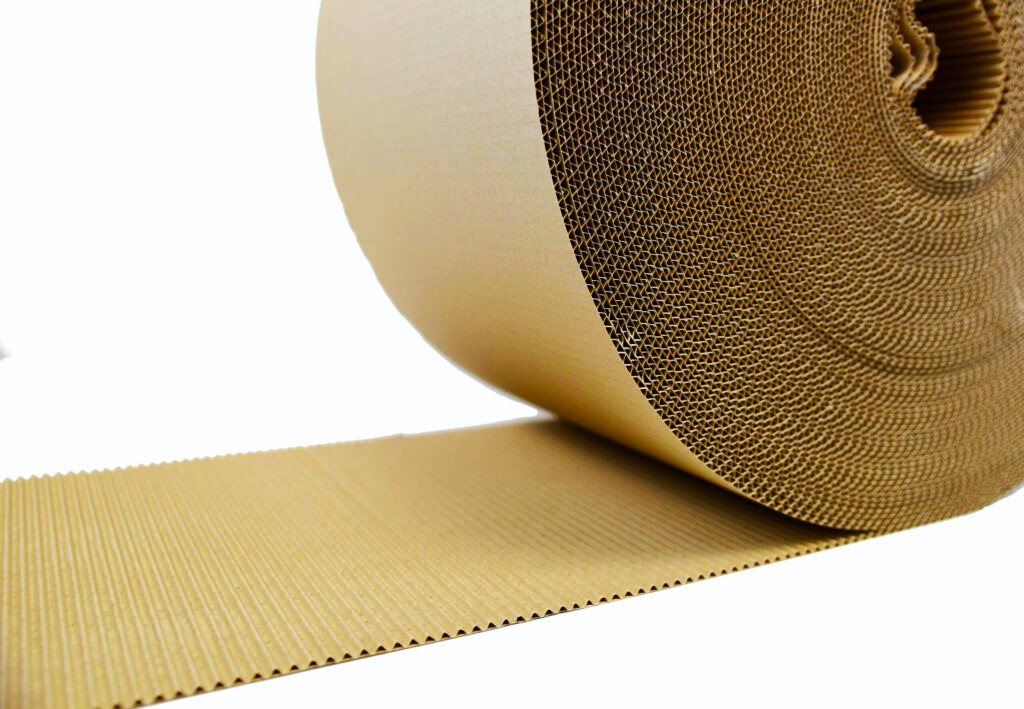

Corrugated rolls can be used to separate products during transit, preventing them knocking together and causing damage. They can also be used to fill the void within the box, by being folded into areas that require more padding.

Manufactured from recycled, and 100% kerbside recycled paper, these rolls are a great sustainable choice.

Recyclable plastic packaging is hardwearing, and due to latest technologies in plastic recycling, can be environmentally friendly.

Plastic void fill is also dust free, and can be reused multiple times.

Air cushion packaging is a popular void-fill solution for many Springpack customers.

Made using recycled materials, they work to form a protective bubble around your products. Filling the box with as much air as possible, air cushions reduce the need to add extra weight to your products. The reduction of weight reduces transport emissions and cost to ship.

Sold on a small roll, Air Cushion packaging is inflated by the user when needed. This means more rolls can be sent per shipment, reducing transport emissions. It also means that they take up considerably less warehouse space than bubblewrap.

Suspension and Retention packaging are commonly used for transporting a wide range of products, such as coffee machines, car parts or mobile phones.

They both offer supreme shock absorption for all shapes and sizes of product, whilst offering a premium unboxing experience to the end user.

Suspension packaging works by suspending the product in the centre of the box, to prevent external forces causing damage, and stop the product moving around. Suspension uses two sheets of plastic film, and sandwiches the product between them.

Just like suspension, retention packaging also provides protection by restricting the product’s movement. It uses a single film sheet that is stretched tightly around the product.

Loosefill, also known as packaging peanuts is a great solution for eco-friendly void fill. Historically, styrofoam peanuts have been used to protect products, though these are not environmentally friendly. Thankfully, more biodegradable products have been invented such as starch-based loosefill.

To pack with Loosefill, simply half fill the box with loosefill, add the product, and fill the box further.

Our Biodegradable loosefill is made from starch and are a popular sustainable packaging solution! They contain no plastic (No biodegradable plastics either!) and can be reused or composted by the end user.

Paper twist fill is made from 100% recycled paper, and can be 100% recycled, kerbside. Used in place of styrofoam packaging peanuts, paper twist fill is a great way of protecting your products during transit.

Who are Springpack?

We are a wholesale packaging distributor based in Worcester. Experts in every kind of packaging, ranging from custom packaging and postal boxes to export freight solutions, we are confident we have a packaging solution that fits your packaging process!

Were Here to Help Guide Inform

If you would like to learn more about Springpack and our services, use the form below to submit an enquiry, or get in touch with one of our packaging experts by…

Author: Alice Jeavons

Springpack is a UK packaging company delivering sustainable solutions that empower customers. We prioritise exceptional service, building strong relationships and developing innovative packaging solutions tailored to unique needs. Sustainability drives us, from eco-friendly materials to reusable practices minimising waste and emissions. As a family-run business, we’ve grown from humble beginnings to industry forerunners. Our passion lies in making a positive impact in our community and the lives of customers, employees, and stakeholders through outstanding service that exceeds expectations.